Custom Induction Coil Design

for Industrial Applications

Tailored Induction Coil Design

ESC Induction specializes in crafting tailor-made induction coil designs that meet the distinct needs of various industrial applications. We understand that each industry has its unique characteristics, which is why our team is dedicated to providing personalized heating solutions that align with your specific requirements. Our extensive expertise in induction coil design ensures both efficiency and accuracy, translating to long-term cost savings for your business.

Choosing ESC means you're not just acquiring a customized coil; you're making a valuable investment in a product that enhances energy efficiency, reduces downtime, and boosts production.

Whether your focus is on manufacturing, automotive, or aerospace, our custom-designed coils are engineered for durability and high performance. As a recognized leader in custom coil manufacturing, our company is relied upon by industries around the globe for our unparalleled expertise and quality.

What Drives Our Emphasis on Precision in Custom Induction Coil Design Services?

Precision in the design of induction heating coils is essential for industrial processes. A thoughtfully crafted coil has a direct impact on energy consumption, ensuring temperature uniformity and enhancing the overall efficiency of your heating system. Inaccuracy can lead to energy wastage, resulting in increased costs and a heightened risk of equipment malfunction.

Each coil is engineered to deliver consistent and efficient heating, tailored to meet the needs of various materials and applications. Poorly designed coils can cause uneven heating, leading to faulty output and resource waste. Selecting the right materials can help mitigate these issues, while our specialized designs elevate performance standards. Additionally, we prioritize durability to ensure reliable operation. Our induction heating coils are engineered to meet the rigorous demands of commercial use.

Beyond enhancing performance, a precisely tailored custom induction heating coil design also lowers operational costs, thereby improving overall efficiency.

What Common Challenges Do Industries Encounter in Induction Heater Coil Design?

Numerous companies encounter challenges when creating induction heating coils. These issues can affect both operational efficiency and overall costs.

Inconsistent Heating

Inconsistent heating is a common problem that can lead to material defects, ultimately diminishing the quality of the final product. This often happens when the coil design is not properly aligned with the specific application requirements.

Energy Wastage

Suboptimal coil designs can lead to increased energy consumption. This escalates power costs, which, over time, can significantly raise production expenses.

Frequent Breakdowns

Another issue is recurrent failures from poor coil design. These breakdowns cause costly downtime, reduced production, and rising repair expenses. Inadequately built coils require constant maintenance, but with ThermESC Intl., you can alleviate the burden of frequent repairs.

Limited Customization

Numerous coil manufacturers provide standard coil designs that may not meet the unique needs of particular industries. If your coil isn’t tailored to your specific heating process, it will not operate at its best.

How We Solve These Problems?

ESC Induction addresses these challenges through tailor-made solutions. Our team works closely with you to create a coil that precisely aligns with your unique requirements. This guarantees consistent heating and improved energy efficiency while also prolonging the life of your equipment. We emphasize the reduction of energy waste and the lowering of routine maintenance concerns. This empowers you to focus on your production with total assurance.

Meets Specific Needs

Customizable design and specs meets your requirements.

Uniform Heating

Uniform heating and energy consumption.

Extends Lifespan

Designed with your production in mind, keeping downtime minimal.

Tailored Induction Coil Design Solutions for Diverse Industrial Applications.

ESC Induction excels in crafting tailored induction heating coil designs for diverse industrial applications. Whether your focus is on heat treatment, forging, automotive, aerospace, or fluid and gas heating, we deliver solutions that align perfectly with your specific needs.

Our Custom Induction Coil Design Process

1. Consultation

We begin by assessing your heating requirements, which involves examining your materials, process conditions, and the distinct industrial application. Our main focus is enhancing the efficiency and performance of your system. Since each customer has unique needs, we design a tailored induction heater that aligns with their specific requirements.

2. Design & Prototyping

Our design team utilizes cutting-edge techniques to create 3D models of your distinctive coil. This process enables us to refine and evaluate the concept thoroughly before moving into production. At every phase, we guarantee the utmost precision. Additionally, we offer a variety of tailored design options, allowing you to choose the best solution according to your production needs.

3. Material Selection

Selecting the right materials is essential for the durability and performance of coils. We exclusively use premium-grade materials, ensuring long-lasting efficiency even in the most challenging industrial settings.

4. Manufacturing & Testing

After finalizing the design, we move on to production. Every coil is subjected to rigorous quality control measures. Our testing phase guarantees that the coil performs effectively in real-world conditions. Our goal is to provide you with a coil that enhances induction heating efficiency, conserves energy, and minimizes malfunctions.

5. After-Sales Support

Once your coil is installed, we will offer ongoing support. Our team of technicians is on hand for maintenance, induction coil repairs, and troubleshooting to guarantee that your coil operates smoothly. Should any issues arise, we are here to help resolve them swiftly.

Reasons to Select Us as Your Induction Coil Manufacturer.

Selecting ESC Induction as your custom coil manufacturer offers numerous advantages compared to rival companies. Here’s what sets us apart:

01

Experience and Expertise

With decades of experience in designing induction coils, we have assisted numerous organizations in enhancing their heating processes. Our team consists of highly skilled professionals who possess a deep understanding of every facet of industrial heating.

02

Tailored Solutions

We do not offer generic solutions. Our team is dedicated to thoroughly understanding your unique requirements. Following this assessment, we develop a tailored induction heater design that enhances the efficiency of your operations.

03

High-Quality Materials

We utilize only premium materials in our coil designs, ensuring that your coil has an extended lifespan. This results in fewer repairs and the ability to withstand challenging industrial environments.

04

Quick Turnaround Times

We understand that time is of the essence in industrial operations. Our streamlined production methods allow us to deliver custom coils swiftly. We uphold superior quality at every stage of the process.

05

Customer Support

Our team offers support from the initial consultation through to post-installation. We also provide maintenance and repair services. This ensures that your coils function optimally.

Testimonials: Success Stories from Our Clients

Our clients serve as our strongest supporters. ESC Induction has collaborated with top companies from diverse industries, delivering tailored solutions that have not only decreased their energy usage but also enhanced production efficiency.

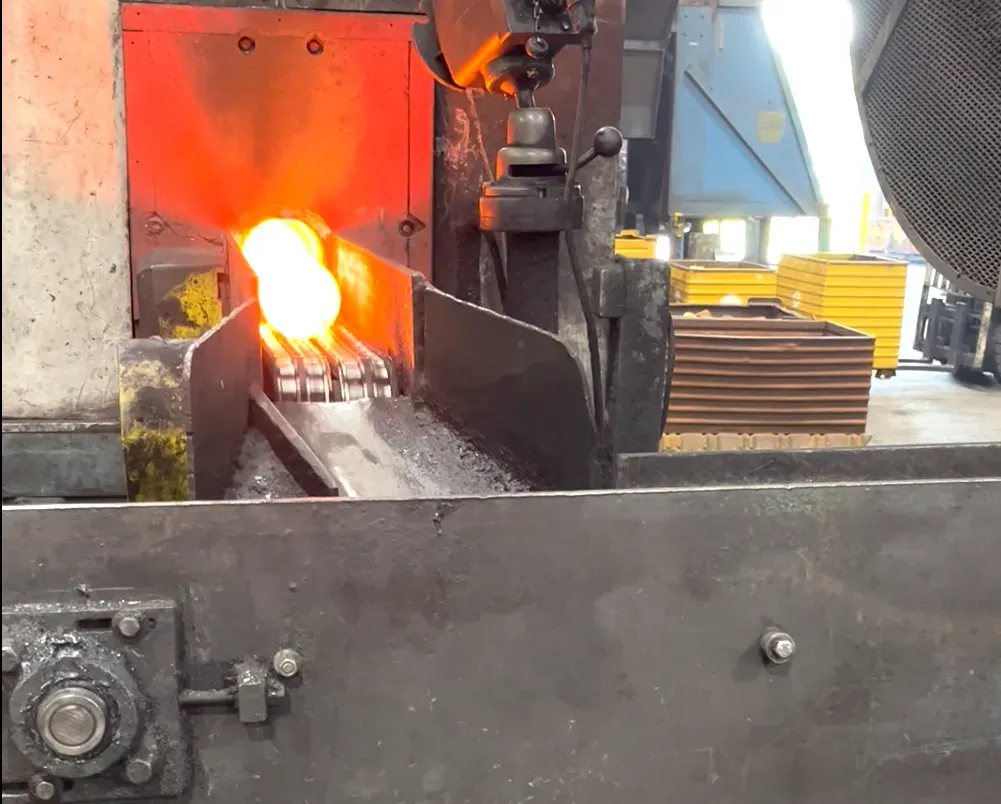

"The ESC system provides quick, clean, and efficient heating of rebar for our forging process. This saves us labor hours, plus not having to use gases saves us in material costs."

Jeffery H.

CMC Commercial Metals

FAQs

Have inquiries regarding our custom induction coils? We have the answers! Explore our FAQ section to discover everything you need to know about our innovative induction heating solutions at ESC Induction.

How long does it take to design and manufacture a custom induction coil?

Our design and manufacturing process typically takes a few weeks, depending on the complexity of the project.

What types of materials do you use in your coil designs?

We use high-quality materials tailored to your specific application, ensuring durability and performance.

Can you design coils for specific industrial applications?

Yes, we specialize in designing coils for a wide range of industries, including automotive, aerospace, and heat treatment.

What kind of post-sale support do you offer?

We provide ongoing maintenance and induction coil repair services to ensure your coil continues to operate efficiently.

How long does it take to design and deliver a custom induction heater?

The timeline for designing and delivering a custom induction heater varies based on the complexity of the requirements. Typically, the process involves initial consultation, design, production, and delivery phases, with lead times communicated during the consultation.

Get a Custom Induction Coil Design Quote Today

Looking for a custom coil design tailored to your industrial needs? Contact ESC Induction today for a free consultation. Our team will assess your heating requirements and provide a quote for a custom coil design that optimizes your process. Call us to get started on your custom induction coil design project.