Induction Heaters Custom to Your Application Needs...

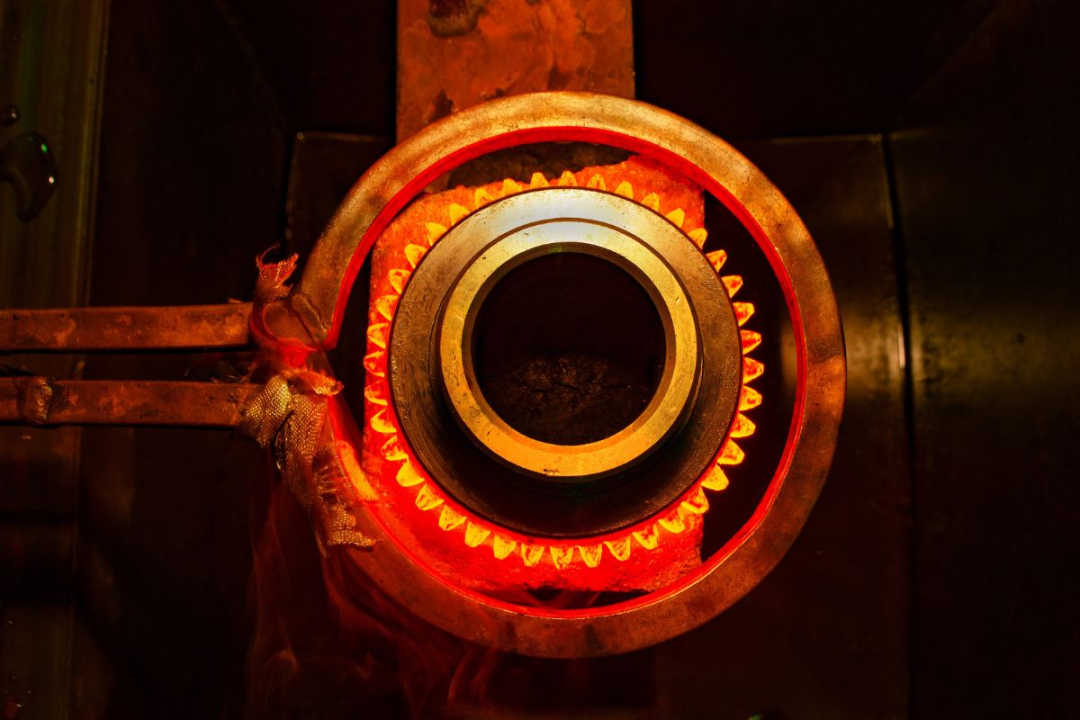

Custom Induction Heaters

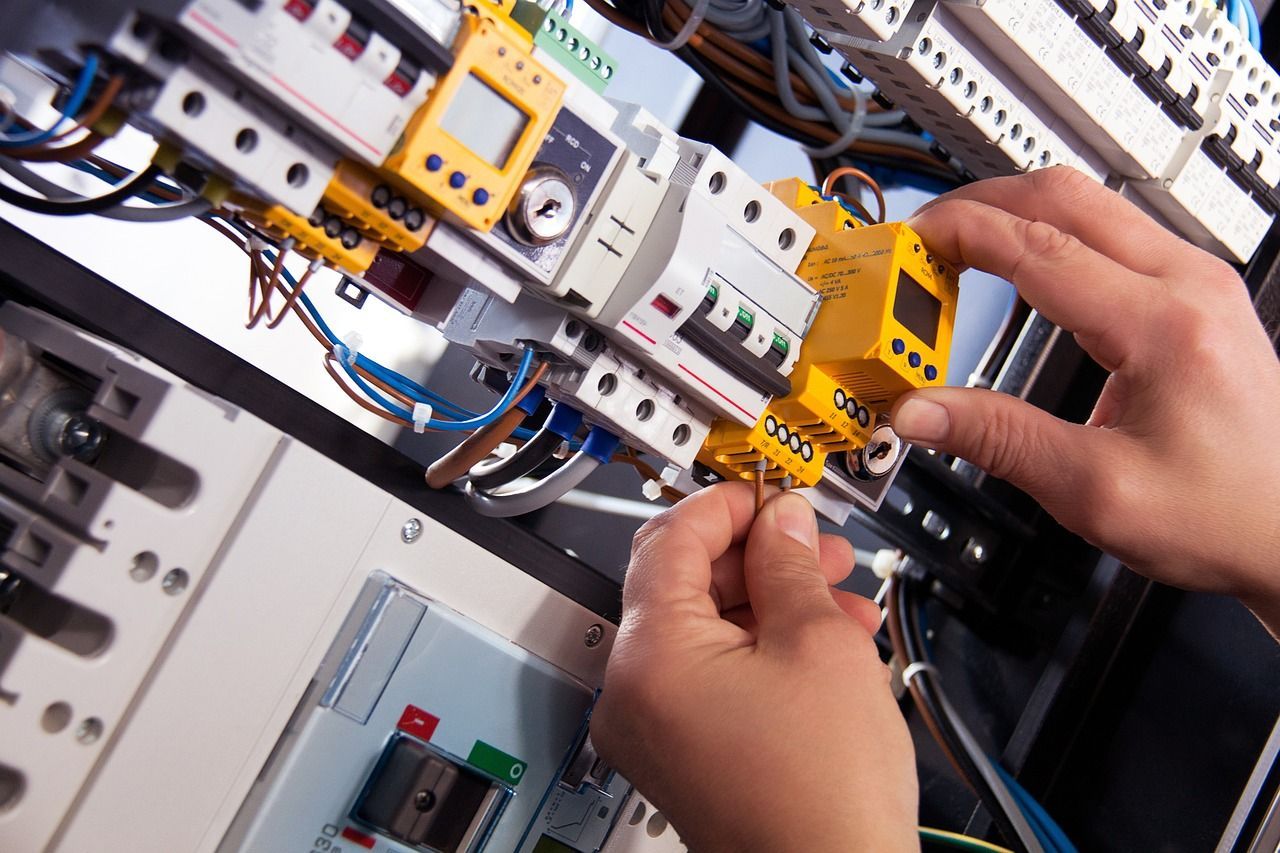

We offer premium custom induction heaters tailored to satisfy your industrial requirements. Our fully customizable, turn-key induction heaters feature PLC-controlled systems.

PLCs have been a staple in industrial settings for years, known for their reliability and user-friendly design for operators and maintenance staff alike.

This reduces the necessity for bespoke circuit boards, enhancing uptime and boosting your company’s productivity.

Allow us to develop a personalized induction heating solution to address all your induction needs, including:

- Touchscreen interfaces

- Mechanical customization

- Material handling for parts.

What is a Custom Induction Heater?

Custom induction heaters represent cutting-edge heating solutions tailored to address distinct operational needs. In contrast to conventional heaters, our custom induction heating systems are engineered to enhance efficiency for particular applications, guaranteeing both reliability and user-friendliness. Whether you require an induction heating system, a heat inductor, or bespoke induction heaters, our expertise positions us to provide superior quality solutions.

Key Features and Benefits of Induction Heating System

Efficiency and Energy Savings

Our induction heaters provide rapid heating while consuming less energy. This efficiency reduces operational costs and minimizes environmental impact, making our custom induction heaters an eco-friendly choice.

Precise Temperature Control

Achieve accurate heating with our sophisticated control systems. Our custom induction heating solutions ensure consistent and precise temperature management, crucial for sensitive applications and product quality.

Rapid Heating Capabilities

Reduce production times with fast and uniform heating. Our induction heaters are designed to deliver rapid heat induction, allowing for quicker process times and increased throughput.

Safety Features

Enhanced safety measures to protect operators and equipment. Our custom induction heaters include built-in safety features such as automatic shut-off, overheat protection, and fail-safe mechanisms to ensure safe operation.

Durability and Reliability

Built to withstand rigorous industrial use. Our custom induction heaters are constructed from high-quality materials, ensuring long-lasting performance and minimal maintenance requirements, even in demanding environments.

Completely Customized

Our induction heating solutions are completely customized to fit your unique production and application needs. Our expert team will work closely with you to ensure the equipment meets your requirements.

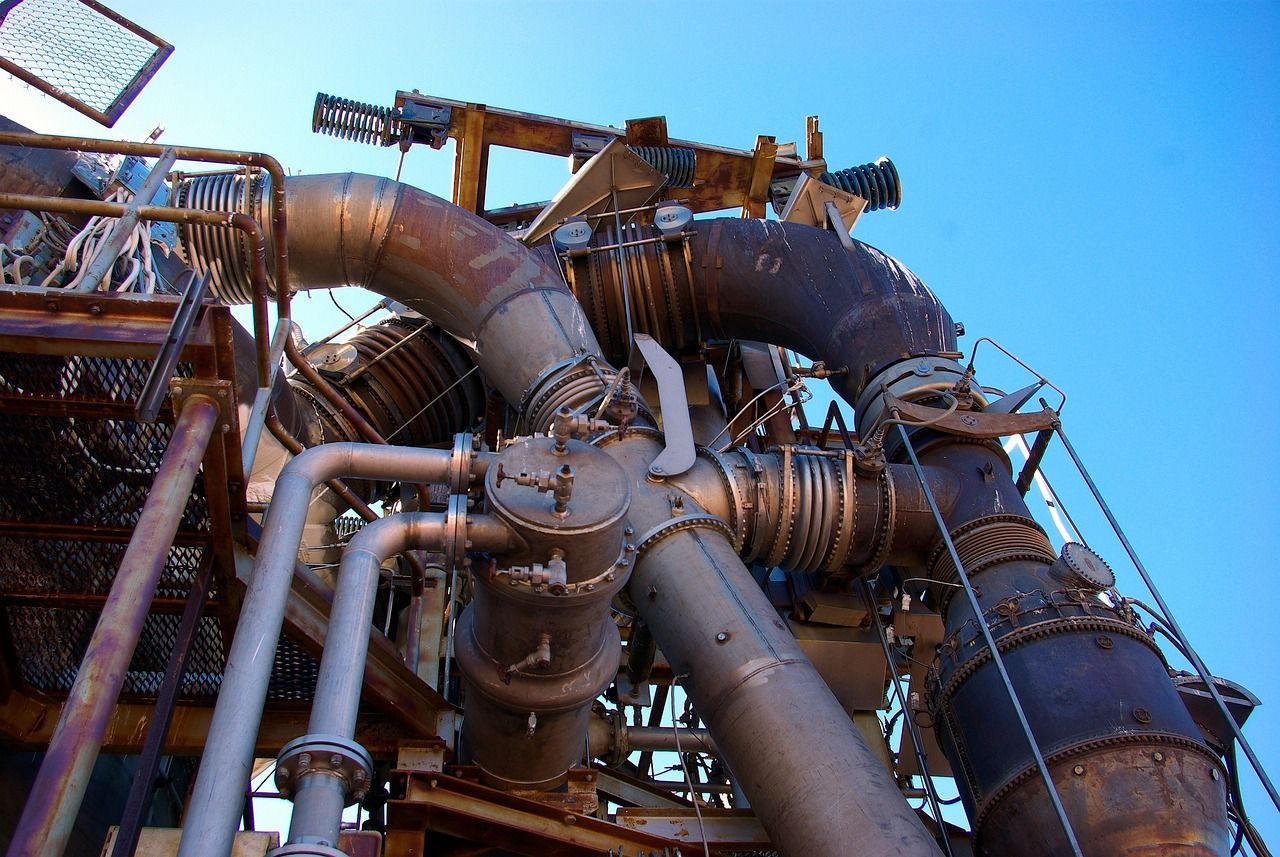

Applications of Custom Induction Heaters

Whether you require accurate heat treating, effective brazing, or dependable melting, our custom induction heaters are designed to fulfill your requirements. Discover how our specialized solutions can enhance your processes and elevate operational excellence.

Technical Specifications

Our bespoke induction heaters are accompanied by comprehensive technical specifications.

Custom Power Range

Customizable power range to meet your requirements.

Custom Frequency Range

Adjustable frequencies for different applications.

Custom Induction Coil Design

Custom coil designs for optimal performance.

How to Order a Custom Induction Heater?

1. Consultation

Get in touch with us to explore your needs for bespoke induction heaters, heat inductors, or tailored induction heating solutions.

2. Design Process

We work alongside you to create the ideal tailored induction heater that fulfills your unique requirements.

3. Production

Our advanced manufacturing process and rigorous quality control guarantee superior induction heating systems.

4. Delivery

We offer prompt delivery and setup support to guarantee your custom induction heater is prepared for immediate use.

Why Choose ESC For Your Custom Induction Heating System?

Opting for ESC Induction for your tailor-made induction heating solutions guarantees that you will receive top-notch products and exceptional services. Here’s why:

01

Experience and Expertise

With years of industry expertise and technical proficiency in custom induction heaters, we deliver personalized solutions that cater to your specific requirements. Our comprehensive knowledge of induction heating and heat inductors guarantees dependable and efficient performance.

02

Quality Assurance

We uphold the utmost standards and certifications, ensuring the quality and dependability of our bespoke induction heaters and tailored induction heating solutions.

03

Customer Testimonials

The success stories we've achieved and the satisfaction of our clients speak volumes about the effectiveness and reliability of our tailored induction heaters. We take great pride in the positive testimonials from our customers who place their trust in us for their induction heating requirements.

04

Commitment to Satisfaction

Our unwavering support and service guarantee your success. From the initial consultation to post-installation assistance, we are devoted to delivering a smooth experience and ensuring your custom induction heater operates at peak performance.

FAQs

Have queries regarding our custom induction heaters? We have the solutions! Explore our FAQ section to discover all you need to understand about our advanced induction heating solutions at ESC Induction.

What is the difference between a standard and a custom induction heater?

A custom induction heater is specifically designed to meet unique operational requirements, offering tailored solutions for specific applications, whereas standard heaters come with predefined specifications and limited flexibility.

How do custom induction heaters improve energy efficiency?

Custom induction heaters provide rapid and localized heating, reducing energy consumption and minimizing heat loss, leading to significant energy savings compared to traditional heating methods.

Can custom induction heaters be used for multiple applications?

Yes, custom induction heaters are versatile and can be designed to accommodate various applications, including heat treating, brazing, annealing, shrink fitting, and more, ensuring optimal performance for each specific use case.

What customization options are available for induction heaters?

Customization options include power range, frequency range, coil design, touchscreen interfaces, mechanical adjustments, and part material handling solutions to match specific industrial needs.

How long does it take to design and deliver a custom induction heater?

The timeline for designing and delivering a custom induction heater varies based on the complexity of the requirements. Typically, the process involves initial consultation, design, production, and delivery phases, with lead times communicated during the consultation.

Still have a question?

Reach out to us! We are always happy to help guide you in the right direction.